Maintaining independence and mobility is a top priority for millions of Americans, and a reliable power wheelchair is the cornerstone of that freedom. However, many users often find themselves facing unexpected repairs or a shortened device lifespan due to a lack of consistent care. By understanding how to properly maintain your equipment, you can ensure that your power wheelchair lifespan remains a dependable partner in your daily life for years to come. This comprehensive guide explores the essential steps to maximize your investment, focusing on preventative measures that save time and money while keeping you moving safely and efficiently through any environment.

For those who rely on high-quality medical consumables to support their daily health needs, equipment longevity is not just a matter of convenience; it is a matter of safety. The power wheelchair lifespan can vary significantly based on usage patterns and the environment, but with the right maintenance routine, you can push that duration to its maximum potential. Following ADA requirements for mobility devices ensures that you are operating within safety standards, but the physical upkeep of the machine relies entirely on the user and their care team. Consistent attention to the battery, tires, and electrical components is the most effective way to prevent the "wear and tear" that often leads to premature replacement of your power wheelchair lifespan critical components.

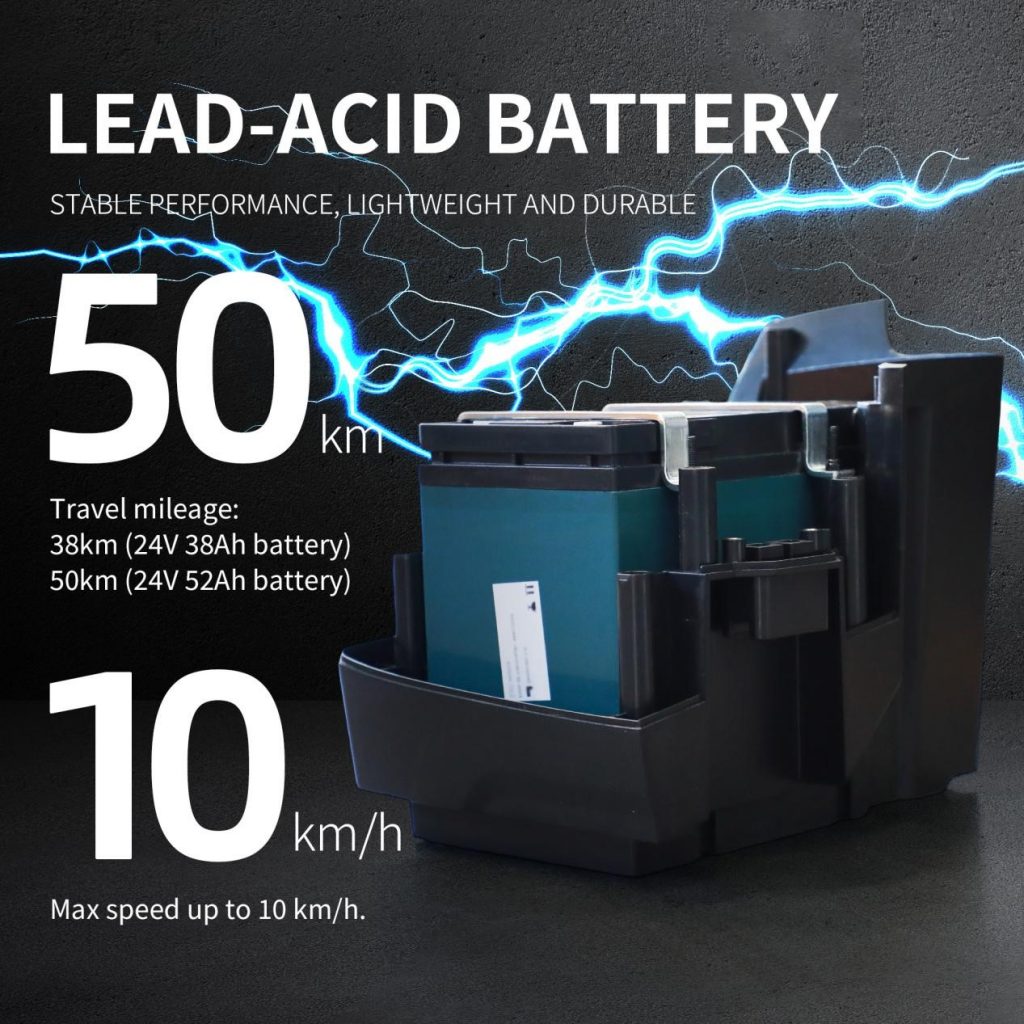

Optimizing the Heart of Your Mobility: Battery and Electronics

The heart of every power wheelchair is its battery system, and proper charging habits are the single most important factor in extending its life. Most modern devices use sealed lead-acid or lithium batteries that require a specific charging cycle to maintain their chemical health. You should avoid letting your battery drain completely, as deep discharges can permanently reduce its capacity. Instead, charge your wheelchair every night, regardless of how much you used it during the day. It is also vital to use the charger provided by the manufacturer, as third-party chargers may not have the correct voltage or safety shut-off features, leading to overheating or internal damage.

Protecting Sensitive Electrical Components

The electrical system, including the joystick and controller, acts as the brain of your device and requires protection from the elements. While many power wheelchairs are designed for outdoor use, they are not waterproof. Moisture is the primary enemy of electrical circuits, leading to corrosion and intermittent failures. If you are caught in the rain, dry the joystick and seating area immediately once you are indoors. For long-term protection, consider using a joystick cover. Furthermore, checking the wire harnesses and connectors for any signs of fraying or loose connections can prevent a sudden breakdown while you are away from home.

Mechanical Integrity: Tires, Casters, and Structural Care

Moving beyond the power source, the structural integrity of your mobility device depends heavily on the condition of your tires and casters. Unlike manual chairs, power wheelchairs carry significantly more weight due to the motor and battery, which places immense pressure on the rubber. Check your tire pressure weekly if you have pneumatic tires, as under-inflated tires force the motor to work harder, draining the battery faster and straining the drive system. If you notice uneven tread wear or cracks, it is time for a replacement. Keeping the wheels clean of hair, lint, and debris is equally important, as buildup around the axles can create friction that damages the bearings over time.

Hygiene and Frame Maintenance for Longevity

Regular cleaning is about more than just aesthetics; it is a critical part of mechanical maintenance. Dust and grime can find their way into the motor housing and moving parts, causing them to overheat or seize. Use a damp cloth with mild soap to wipe down the frame and seating system, avoiding high-pressure water sprays that could penetrate the electronics. Paying attention to the upholstery is also important for skin health, as worn-out cushions or torn fabric can lead to improper pressure distribution.

Professional Servicing and Compliance Standards

Professional inspections should be scheduled at least once a year to address technical issues that are not visible to the naked eye. A qualified technician can check the motor brushes, test the battery health, and ensure that the braking system is responsive and safe. These annual checkups are often covered by Medicare guidelines if the equipment is deemed medically necessary, making it a cost-effective way to catch minor issues before they become expensive repairs. Staying proactive with professional servicing ensures that your device remains compliant with RESNA standards, which are the gold standard for assistive technology safety in North America.

As a leading global Power Wheelchair manufacturer, INTCO Medical is dedicated to providing innovative solutions that enhance the quality of life for people with disabilities. Our commitment to excellence extends from our advanced physical therapy resources to our wide range of rehabilitation products designed for durability and comfort. We believe that mobility is a right, and we work tirelessly to ensure that every product we create meets the highest international standards for performance and safety.

At INTCO, we understand the challenges faced by wheelchair users and their caregivers. By combining state-of-the-art technology with user-centric design, INTCO Medical continues to set the benchmark in the healthcare industry as a premier Power Wheelchair manufacturer. Whether you are looking for the latest in power mobility or essential medical consumables, our team is here to support your journey toward independence with reliable equipment and expert guidance.

Frequently Asked Questions About Power Wheelchair Care

How long does a power wheelchair typically last?

On average, a high-quality power wheelchair lasts between 3 to 5 years, though many users can extend this to 10 years with meticulous care. The actual lifespan depends heavily on the frequency of use, the terrain encountered, and how strictly you follow a preventative maintenance schedule. As a leading Power Wheelchair manufacturer, INTCO Medical designs units for long-term durability, but routine battery and motor care remain essential for longevity.

Can I overcharge my power wheelchair battery?

Most modern chargers provided by manufacturers like INTCO feature automatic shut-off sensors to prevent overcharging. However, it is a best practice to unplug the charger once the indicator shows a full charge. Avoiding extreme temperatures and never letting the battery drop to 0% charge are the most effective ways to preserve the chemical integrity of your power cells.

Is it safe to use my power wheelchair in the rain?

While power wheelchairs are built to handle various environments, they are not waterproof. Exposure to heavy rain or standing water can damage sensitive electrical circuits and the joystick controller. If your chair gets wet, wipe it down immediately with a dry towel. For users in wet climates, investing in a specialized weather cover for the electronics is highly recommended to prevent long-term corrosion.

How often should I check the tire pressure on my wheelchair?

You should check your tire pressure at least once a week. Under-inflated tires increase friction, which significantly reduces your battery range and puts unnecessary strain on the motors. Maintaining the correct PSI (pounds per square inch) ensures a smoother ride and protects the mechanical components of your rehabilitation products from premature wear.

Where can I find replacement parts or professional servicing?

It is always best to source parts directly from an authorized dealer or the original manufacturer to ensure compatibility and safety. For technical support, replacement medical consumables, or maintenance advice, you can contact us directly. Regular professional servicing by a certified technician is the best way to ensure your device remains safe and compliant with all mobility standards.